Corrugated metal sheet is a tough light weight and weather resistant material that provides advanced protection qualities that cannot be matched by any other type of material.

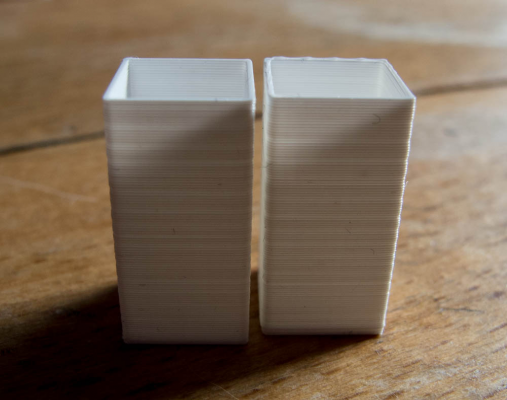

Ribiing sheet metal for strength.

Our experts can roll form a variety of sheet metal configurations to suit your needs.

From siding to roofing interior uses exterior uses and more.

These corrugated panels are made of rippled metal sheets one of the most commonly used panels in the industry.

Each groove bead or line will compound the strength and can also add a design to the panel.

The corrugations in the panels increase the bending strength of the sheets in the direction perpendicular to the corrugations.

Corrugated sheet metal is a tough material light weight weather resistant and practical for many different uses.

Pressing grooves ribs or designs into a piece of sheet metal will greatly increase the strength.

Ribbed metal sheet trapezoidal characteristics opaque enclosures built with panels of sheet steel 0 50mm.

A common way to add strength to a sheet metal part is to introduce a bend or beaded emboss.

We offer a broad selection of steel panel profiles including corrugated wide rib low profile and many more.

One such function is to add strengthening ribs.

Thickness folds in horizontal or vertical position depending on installation process poles of 60 x 40 x 1 5mm rectangular tube straps and.

Corrugated metal panels are.

Sheet metal with structural grooved seams.

A seam is a joint where the two ends of the sheet meet.

Wire edging has been a widely used sheet metal strengthening method for a long time.

The stretched metal in those areas will hold tension in the panel and give it structural rigidity.

As the material is deformed the effective material thickness increases and the material becomes stronger.

Grooved seam grooved seam is one the most effective ways to provide strength to the sheet metal especially when you want a round shape pipe from the sheet.

If the chosen sheet metal cannot be formed into the desired shape under the selected processing conditions the applied stresses are higher than the tensile strength of the sheet metal which causes cracks to form in the part.

Sheet metal has a high strength to weight ratio and good malleability that can provide form and structure to products but because it is flat and bends easily it doesn t always work.

Here are some ways to increase the structural strength of flat sheet stock without adding gussets or increasing the weight of the product.

Our premium metal panels are ideal for your light gauge metal roofing and building needs.

Our premium metal roofing panels are backed by a 40 year paint 30 year chalk and fade and 20 year limited warranty.

The original shape is the flat sheet metal and formed components need to retain their shape permanently.