1 1 2 x d g l where.

Rivet sheet metal thickness.

The aluminum alloy plate and the copper plate are 0 8 0mm.

This determines the required grip of the rivet you select.

Known as peel style rivets the body splits into four legs to fasten plastic and fiberglass to thin material such as sheet metal.

You must select a rivet with a grip range that includes the work thickness required.

According to the sheet metal handbook the length of a rivet is measured from the underside of the head to the tip of the stem.

A best practice is to choose a rivet with a grip range that your total material thickness falls within without being at the minimum or maximum of that grip range.

Following the example previously a material thickness of 0 30 inches falls comfortably within the 0 251 0 375 inch grip range of our chosen pop rivet.

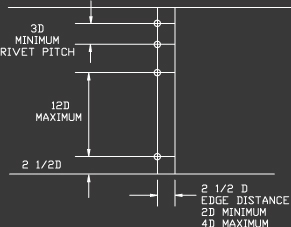

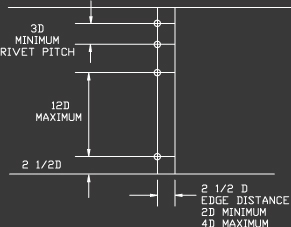

A general rule is that the rivet should have a diameter of at least three times the thickness of the thickest sheet that is being joined.

The length of the rivet should equal the sum of the thickness of the metal plus 1 1 2 times the diameter of the rivet as shown in figure 13 43.

According to the military standard so the bucked counter head diameter of the rivet joint must be larger than 1 4 times the diameter of the shank.

Measure the total thickness of the materials to be joined.

Wide thickness range domed head blind rivets.

Rivet nuts also know as rivnuts blind nuts or nut serts are internally threaded inserts used in applications with small material wall thickness.

The length of the rivet should be equal to the thickness of both objects you are fastening plus 1 5 times the diameter of the rivet s stem.

If you are going to join two metal plates with a grip of 13 mm and want to use a 4 8 mm diameter blank rivet the rivet must be 18 mm long.

The low carbon steel plate is 0 8 5 mm.

Therefore the sheet metal parts with the rivet nut column and the rivet nut are not as stainless steel as possible.

Select black or white to make your rivets stand out or blend in.

D the rivet diameter g the grip total thickness of material and l the total length of the rivet.

What length of 4 mm diameter rivet is required to form a snaphead and join two pieces of 1 6 mm sheet metal together.

Use the table below to determine the length of the blind rivet.

The total length of shank required is equal to the total thickness of the metal to be joined plus the allowance for making the head i e.

The height must extend to 0 3 times the diameter of the shank.

Remember that insufficient rivet length will not allow proper formation of the secondary head at the back of the work.

The formula for determining rivet length is as follows.

Fastenright supply all types of rivet nut for use in thin walled materials in a variety of materials and finishes.

The greater the diameter of the blind rivet the stronger the join.

Two piece press fit rivets for leather and fabric.